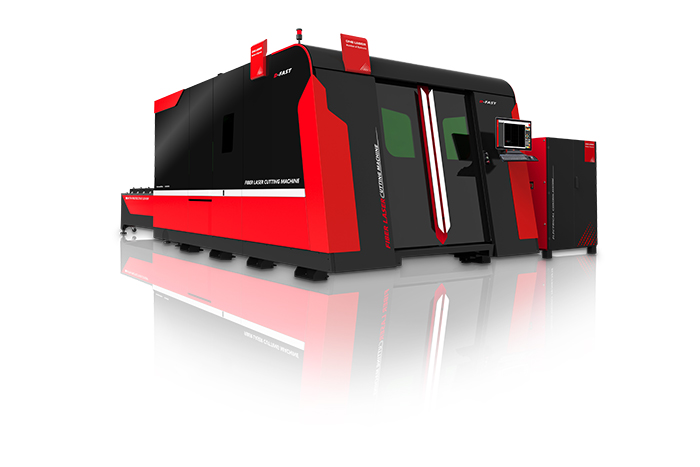

High Power Fiber Laser Cutter FCCBD

The high power fiber laser cutting system (fiber power options ranging from 3000W to 15000W), is fully enclosed and equipped with shuttle platform. This laser machine designed for high power laser cutting thick sheet metal demands, which can cut capable of max. thickness of 30mm stainless steel and 28mm mild steel. KSA Machinery offers the largest available selection of laser cutting innovative. Our user-friendly laser cutting machines with outstanding performance ratios will meet your specific demands and metal fabrication needs.

- Electric power

- Automotive manufacturing

- Electrical equipment

- Commercial kitchen equipment and appliances

- Advertising signs

- Automotive sheet metal production

- Heavy equipment precision parts

- Metal fabrication

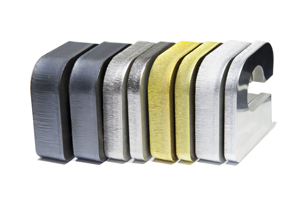

- Stainless steel

- Mild steel

- Galvanized steel

- Electrolytic plate

- Brass plate

- Aluminum plate

- Manganese steel

- Various alloy plate

- Rare metal plate

The power of this series of fiber laser cutting machine is very high. There is no problem in cutting plates and workpieces of various thickness. Therefore, in addition to the ordinary metal products cutting processing, the machine can also be used in the shipbuilding industry, aerospace industry, railway industry and other higher requirements of large-scale engineering construction.

Laser cutting does not require mold fabrication. As long as the drawing is made on the computer, the product can be produced immediately.

With automatic tracking system, it can not only complete plane cutting, but also complete various curved surface cutting.

The surface after cutting is very smooth, which not only reduces the follow-up processing, but also enables the fiber laser cutting machine to adapt to the exquisite small handicraft production.

- Fiber laser cutting machine can be 2 ~ 3 times the cutting speed of CO2 laser cutting machine

- This laser cutting machine requires no start-up time and consumes less cooling water. Besides, it can reduce operating costs and save energy.

- Fiber laser cutting machines work in enclosed spaces to prevent dust and eliminate light pollution.

- This equipment can be equipped with pipe cutting system to complete the cutting of various metal pipes. You can learn more here:Sheet and Tube Fiber Laser Cutter FCCD

If you are looking for a cutting machine that can achieve rapid and accurate metal cutting, our fiber laser cutting machine is a good choice. Whether it is a metal processing plant or a company producing customized metal parts, our laser machine can meet your requirements.

| Power | 3000W | 4000W | 6000W | 8000W | 10000W | 12000W | 15000W |

| Maximum power consumption | 22kW | 25kW | 31kW | 39kW | 46kW | 52kW | 65KW |

| Demand for electricity | 380V,50Hz/60Hz,60A | ||||||

| Repeated positioning accuracy | ±0.02mm | ||||||

| Cutting table | 1500×3000mm²,1500×4000mm²,2000×4000mm²,1500×6000mm²,2000×6000mm² | ||||||

| Floor area | Take 1500*3000mm shuttle table as an example, its floor space is generally 9000*5000mm, which can also be customized | ||||||

| Cutting speed | depends on the type and thickness of the material | ||||||

| Materials | 3000W | 4000W | 6000W | 8000W | 10000W | 12000W |

| Stainless steel | 12mm | 14mm | 20mm | 22mm | 25mm | 30mm |

| Carbon steel | 20mm | 22mm | 24mm | 30mm | 40mm | 28mm |

| Brass | 10mm | 12mm | 14mm | 16mm | 20mm | 20mm |

| Galvanized sheet | 5mm | 6mm | 6mm | 8mm | 8mm | 10mm |

| Aluminum | 10mm | 12mm | 14mm | 17mm | 20mm | 20mm |

All fiber lasers used in high power laser cutting machines are IPG brand. IPG is the world's largest fiber lasers manufacturer. They provide high quality fiber laser for all our fiber laser cutting machines. The photoelectric conversion efficiency of these fiber lasers can reach 30%, and the service life can reach more than 100,000 hours.

On the other hand, under thousands or even tens of thousands of watts of ultra-high power, the heat dissipation performance of fiber laser is very critical for maintaining a good operation. Although the IPG laser has its own cooling device, we have made a more comprehensive design: we have installed a high-precision constant temperature and humidity control system in the cabinet used to install the laser, which can more effectively ensure the stable operation of the laser in a benign environment.

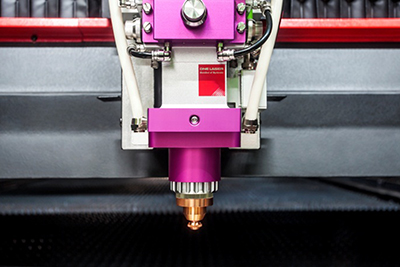

To cut a thicker plate, the cutting head needs to be equipped with a lens with a longer focal length to get a laser beam with a high enough energy density. Moreover, only when the output power of the laser cutting machine is high enough, it can meet the working requirements of the long focal lens.

All the cutting heads of high-power fiber laser equipment are designed and manufactured by Swiss Bystronic. Swiss Bystronic has 40 years of laser cutting equipment processing history and experience, to make the optical structure of cutting head reasonable and ensure high enough beam quality and focusing ability.

High power laser cutting machine must have enough strength and reliability, in order to ensure that even at the 10000-watt level power, cutting machine still can complete fast cutting.

To ensure the stability and durability of the machine structure, we adopted the following processing technology:

1. Two large CNC high temperature electric furnaces are dedicated to the machine structure for annealing and relieving stress.

2. The coating of machine structure surface is fully hand-brushed. The hand-brush coating can make the service life of tool machine body extend 20 years at least.

The operating system of the laser cutting machine was developed by Swiss Bystronic engineers cooperated with system developers in Shanghai.

This is a very intelligent touch screen control system. The operation interface is more simple, convenient and flexible, which can save the operator's time through many details and avoid some wrong operation, and ultimately help you improve the efficiency in the whole production.

- Side-hanging pipe-cutting table: this equipment can cut up to 3 meters of pipe material. The pipe-cutting equipment is attached to the structure where the machine tool is connected with the cross-beam and there is no other support in the middle. The pipe can be rotated unilaterally with the cutting direction.

- Floor-standing pipe-cutting table: this device can cut up to 6 meters of pipe material. Compared with the side-hanging pipe-cutting table, the middle of the pipe cutting table is provided with automatic support, and an additional guide rail and a driving motor are installed. The guide rail can automatically transfer materials, and the drive motor can realize completely synchronous rotation with cutting direction. Centering clamping can be done manually or automatically.