Home / Fiber Laser Cutting System

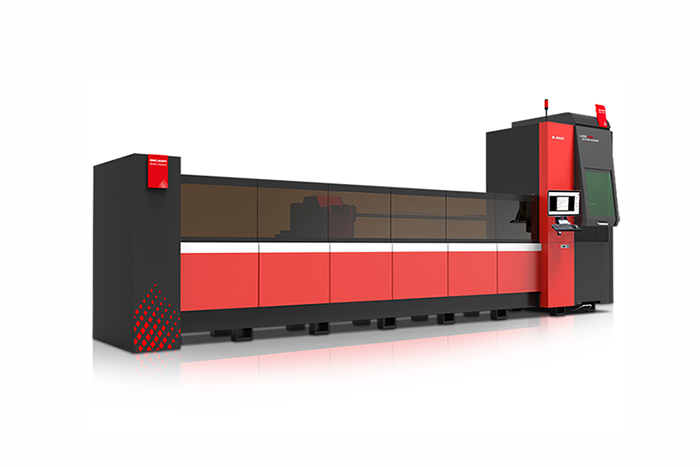

Fiber Laser Cutting System

Fiber lasers output high laser energy density laser beam that focuses on the surface of the workpiece, so that the irradiated area is instantly melting and gasified. Advantages of optical fiber laser cutting machine are high beam quality, stable beam, and low heat output, with no thermal damage to the workpiece, suitable for cutting difficult metal materials, such as copper and zinc, cutting ultra-thin materials and small and complex geometric parts.

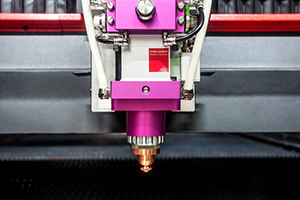

Laser cutting head

(The laser cutting head designed by bystronic , using the latest core lens group .with this core lens group ,the laser beam energy of IPG can be maximized used and the spot quality can be optimized to work on piece surface , we realize the maximum energy utilization of laser beam . the energy of available laser beam is enhanced and the beam mode and beam quality become optimized .after the reflection ,suppression and screening of diffuse light ,secondary and tertiary recycling of the scattered light is used again ,no matter the thin or thick plate ,the perforating time is shortened ,the production efficiency is improved , the most important the cutting speed advantage in both thin and thick plate is increased and the cutting cross section is more bright and delicate .with the bystronic designed lens set we further improve the cutting quality and speed , overall efficiency has increased by 10-15 %)Laser sources

Laser Source is equipped with special cooling device to keep the indoor and the outdoor temperature always consistent, so that the fiber laser can work in a stable environment for a long time to extend the service life of laser cutting equipment.The cutting machine structure is designed by Swiss Bystronic

The body structure of the new generation D-FAST cutting machine is designed by Swiss Bystronic and debugged by the professional technical team from Bystronic headquarter. The laser equipment has characteristics of higher stability, better cutting quality and faster cutting speed.Light barrier design

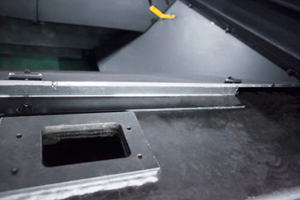

For the safety of operators, we added a thickened metal light barrier plate in laser cutting machine. For the cutting equipment of 750w-1500w, we use the metal light barrier plate with a thickness of 6mm, while for the cutting equipment of 2000-4000w and 6000-10000w, 8mm metal light barrier plate and 10mm metal light barrier plate are respectively used.Stress-relief treatment

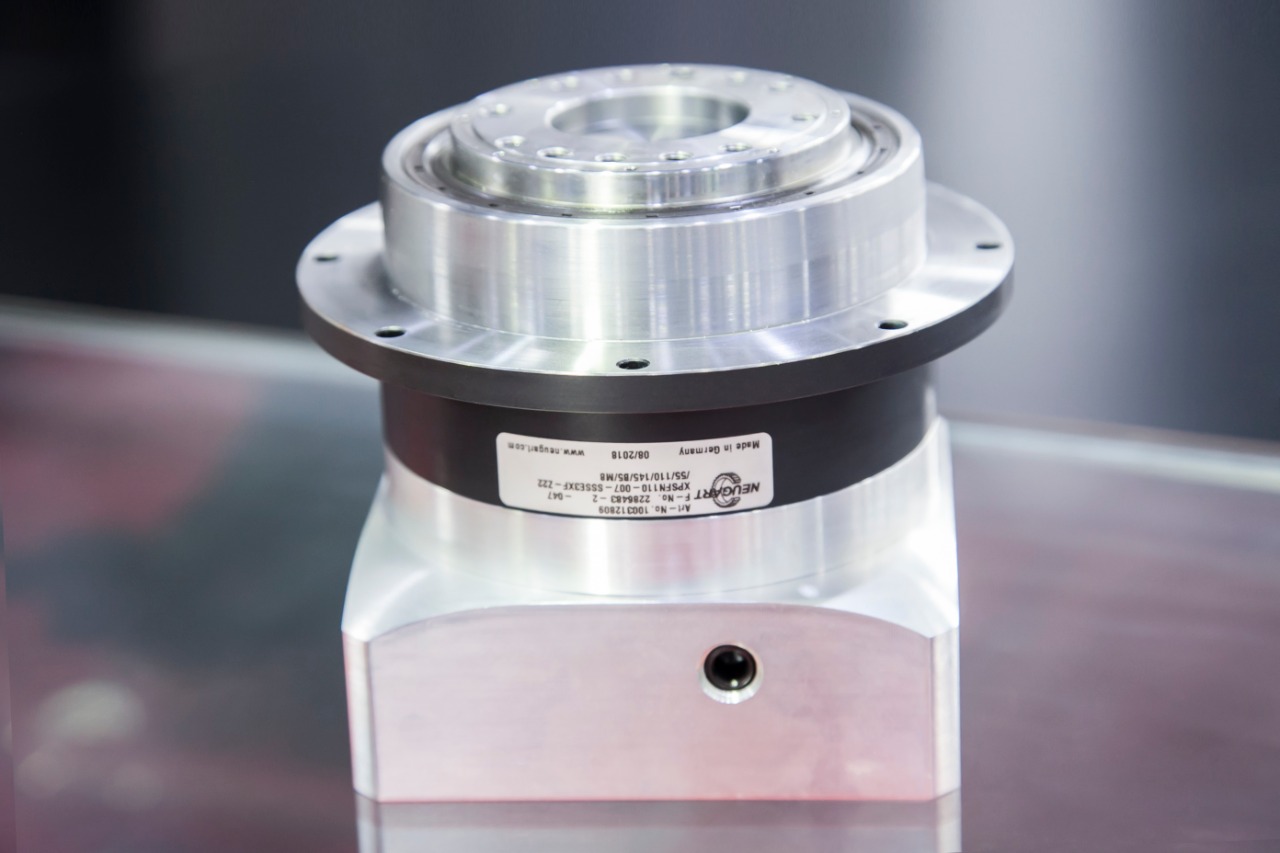

There are two large high temperature numerical control electric furnaces used for the stress-relief treatment of the machine tool, to ensure the accuracy of the machine tool is stable for a long timeThe Rack and Pinion system

imported M3 helical gear , the force is balanced, the synchronization error on both sides doesn’t exceed 0.02mm , fast cutting speed and high precision , and the controllability is much better than othersThe following fiber laser cutting machines are designed to consistently meet the high demands of the metal processing industry.